Kohler Aegis LH640 User Manual Page 13

- Page / 20

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

13

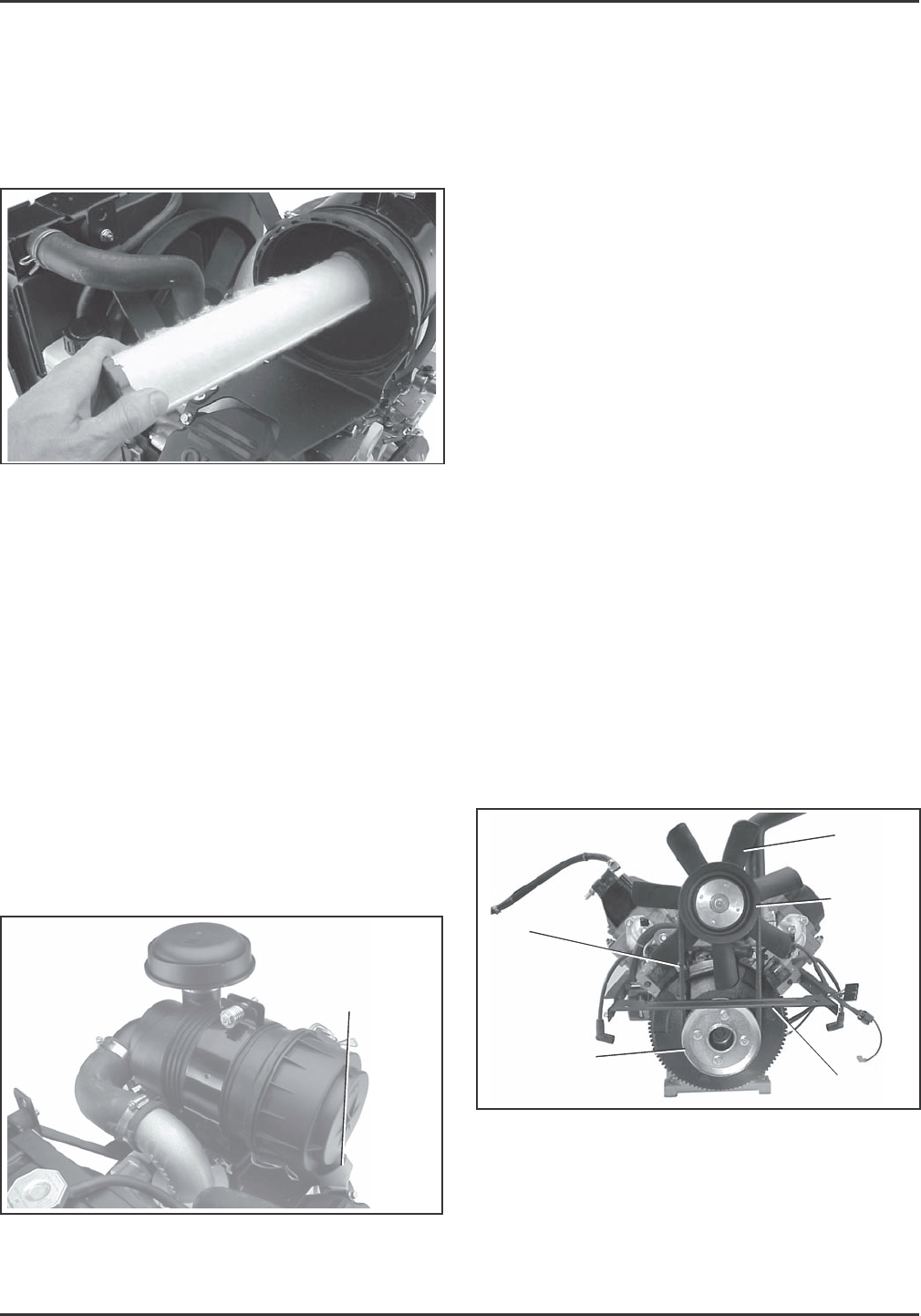

3. After the main element is removed, check the

condition of the inner element. It should be

replaced whenever it appears dirty, typically

every other time the main element is replaced.

Clean the area around the base of the inner

element before removing it, so dirt does not get

into the engine. See Figure 17.

Figure 17. Removing Inner Element.

4. Do not wash the paper element and inner

element or use pressurized air, this will damaged

the elements. Replace dirty, bent, or damaged

elements with new genuine Kohler elements as

required. Handle new elements carefully; do not

use if the sealing surfaces are bent or damaged.

5. Check all parts for wear, cracks, or damage.

Replace any damaged components.

6. Install the new inner element, Kohler Part No.

25 083 04-S followed by the outer element, Kohler

Part No. 25 083 01-S. Slide each fully into place in

the air cleaner housing.

7. Reinstall the end cap so the dust ejector valve is

down and secure with the two retaining clips.

See Figure 18.

Air Intake System and Air Cleaner

Components

Air Cleaner Housing/End Cap Assembly

Make sure air cleaner housing including the dust

ejector valve and the end cap is in good condition and

not cracked. The two retainer clips should positively

lock when cap is installed.

Air Cleaner Hose

Inspect the air cleaner hose to make sure it is not

cracked, split or damaged. Check that the air cleaner

hose is securely clamped to both the air cleaner outlet

and the inlet elbow on the carburetor.

Air Cleaner Mounting Base

Make sure the base is securely fastened to the upper

valve cover screw locations and the screws securing

the clamp bracket for the air cleaner housing are

properly installed and tight.

Breather Tube

Make sure the tube is in good condition and is

properly secured to both the breather cover and

elbow adapter.

Cooling Fan Assembly, Belt, and Drive Pulleys

The cooling fan assembly, used to draw the air in and

across the radiator, is attached to a hub and pulley

assembly with sealed ball bearings. It is belt driven

by a lower split pulley attached to the flywheel and

requires very little service or maintenance. DO NOT

operate the engine without the fan and cooling

system functioning properly, or engine damage will

occur. See Figure 19.

Dust Ejector

Valve

Figure 18. Air Cleaner Assembly.

Belt

Cooling

Fan

Pulley

Assembly

Radiator

Support

Lower

Split Pulley

Assembly

Figure 19. Cooling System Belt Drive (Cover and

Radiator Removed For Clarity).

1. Inspect the fan for any cracks, damaged/missing

fan blades, and secure mounting.

2. The bearings, within the bearing carrier in the

hub of the pulley, should rotate smoothly,

without roughness, binding, or play/wobble.

- OWNER'S MANUAL 1

- Safety Precautions 2

- California 2

- Proposition 65 Warning 2

- Safety Precautions (Cont.) 3

- Oil Recommendations 4

- Fuel Recommendations 5

- Engine Identification Numbers 5

- Operating Instructions 6

- Starting 7

- Operating 7

- Maintenance Instructions 8

- Check Oil Level 9

- Components 13

- Check Spark Plugs 14

- Battery Charging 15

- Adjustments 16

- Troubleshooting 17

- Specifications 18

- Parts Ordering 18

- Major Repair 18

- KohlerEngines.com 20

(120 pages)

(120 pages)

Comments to this Manuals