Kohler Command Pro CV980 User Manual Page 32

- Page / 138

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

5.4

Section 5

Fuel System and Governor

Troubleshooting Checklist

When the engine starts hard, runs roughly or stalls

at low idle speed, check the following areas before

adjusting or disassembling the carburetor.

ȱ Ȋȱ ȱȱȱȱȱȱęȱȱǰȱȱ

gasoline.

• Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

• Make sure fuel is reaching the carburetor. This

ȱȱȱȱȬěȱǰȱȱ

ȱęȱǰȱȬȱȱęǰȱȱȱȱ

fuel pump for restrictions or faulty components

as necessary.

• Make sure the air cleaner base and carburetor are

securely fastened to the engine using gaskets in

good condition.

• Make sure the air cleaner element (including

precleaner if equipped) is clean and all air cleaner

components are fastened securely.

• Make sure the ignition system, governor system,

¡ȱ¢ǰȱȱĴȱȱȱȱ

are operating properly. If the engine is hard-

starting, runs roughly, or stalls at low idle speed,

it may be necessary to adjust or service the

carburetor.

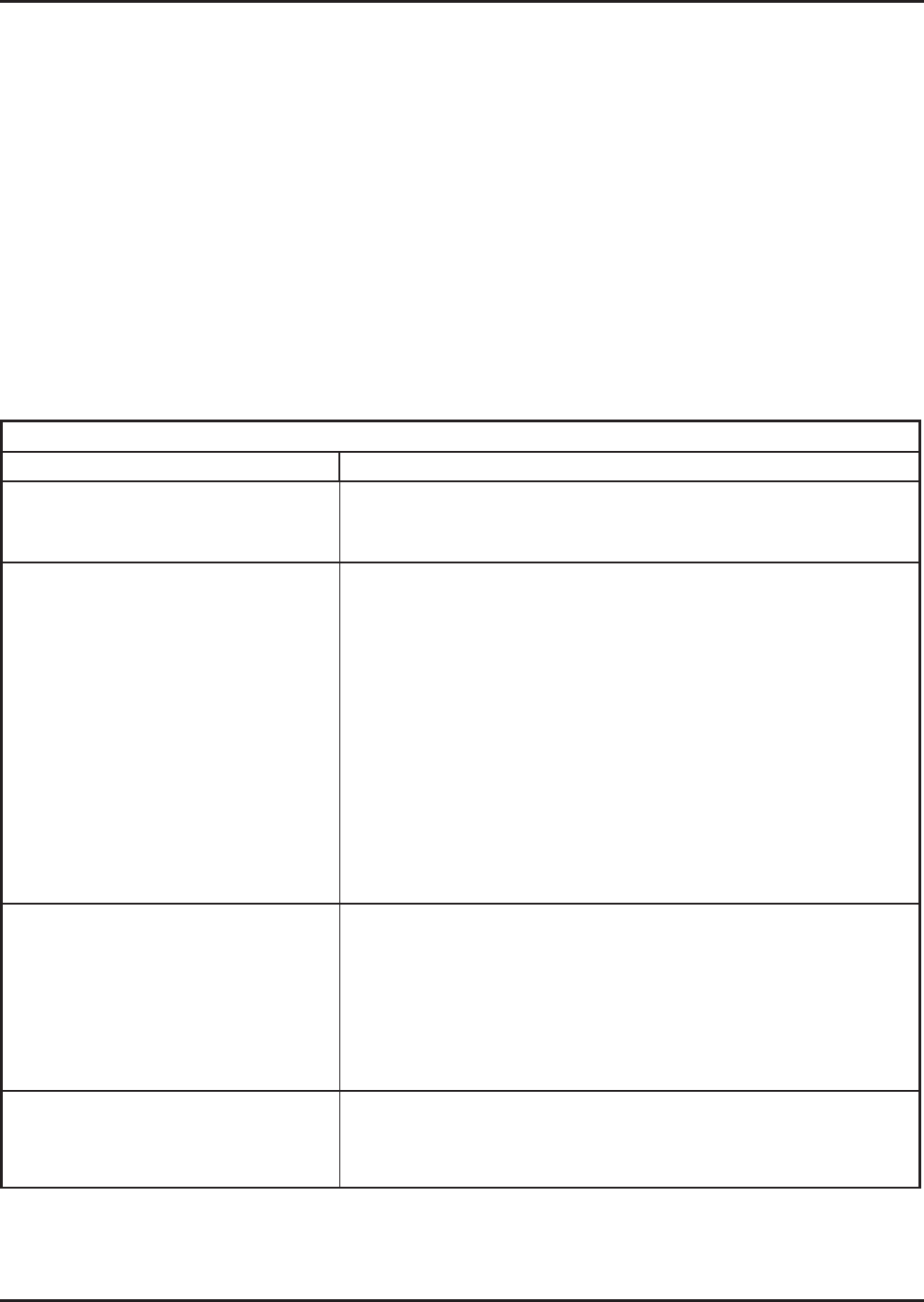

Troubleshooting – Carburetor Related Causes

Condition Possible Cause/Probable Remedy

ȱ ŗǯȱ ȱȱǰȱȱ¢ȱ

or stalls at idle speed.

ȱ ŗǯȱ ȱȱȱ¡ȱǻȱǼȦȱ¢ȱ

ǯȱȱȱȱȱȱǰȱȱȱȱȱȱ

fuel needle.

ȱ Řǯȱ ȱȱȱǻȱ¢ȱ

black, sooty exhaust smoke,

ęǰȱȱȱȱȱǰȱ

governor hunting, or excessive

ĴȱǼǯ

ȱŘǯȱ ȱȱǯȱȱȱǯ

ȱ ǯȱ ȱ¢ȱȱȱǯȱȱȱȱȦ

linkage to ensure choke is operating properly.

ȱ ǯȱ ȱȱȱ¡ȱȱ¢ȱǯȱȱȱȱ

fuel needle (some models).

d. Float level is set too high. Separate carburetor air horn from

ȱ¢ǰȱȱĚȱȱȱȱȱ

procedure.

e. Dirt under the fuel inlet needle. Remove needle; clean needle

and seat and blow with compressed air.

f. Bowl vent or air bleeds plugged. Remove low idle fuel adjusting

needle. Clean vent, ports, and air bleeds. Blow out all passages

with compressed air.

ȱ ǯȱ ¢ǰȱȱȱȱĚǯȱȱĚȱȱȱȱ

leaks.

ȱ řǯȱ ȱȱȱǻȱ¢ȱ

ęǰȱȱȱȱȱǰȱ

governor hunting or excessive

ĴȱǼǯȱ

ȱřǯȱ ȱȱȱ¡ȱȱ¢ȱǯȱȱȱȱ

fuel needle (some models).

b. Float level is set too low. Separate carburetor air horn from

ȱ¢ǰȱȱĚȱȱȱȱȱ

procedure.

c. Idle holes plugged; dirt in fuel delivery channels. Remove low

idle fuel adjusting needle. Clean main fuel jet and all passages;

blow out with compressed air.

4. Fuel leaks from carburetor. ȱŚǯȱ ȱȱȱȱǯȱȱ¢ȱŘǯ

ȱ ǯȱ ȱȱȱȱǯȱȱ¢ȱŘǯ

c. Bowl vents plugged. Blow out with compressed air.

d. Carburetor bowl gasket leaks. Replace gasket.

- SERVICE MANUAL 1

- COMMAND PRO 1

- Contents 3

- Section 1 10

- Tools & Aids 19

- Section 2 19

- Section 3 23

- Troubleshooting 23

- Section 4 27

- Section 5 29

- Fuel System and Governor 29

- Test Conclusion 30

- Disassembly/Overhaul 37

- Section 6 45

- Lubrication System 45

- Operating 46

- Range 46

- Section 7 51

- Temperature Battery Required 53

- Fixed Timing System 54

- Operation 56

- $PS5HFWL¿HU5HJXODWRUV 64

- Section 8 77

- Disassembly 77

- Section 9 100

- Inspection and Reconditioning 100

- Section 10 107

- Reassembly 107

- KohlerEngines.com 138

(20 pages)

(20 pages)

(120 pages)

(120 pages)

Comments to this Manuals