Kohler Generator Sets 20--2800 kW User Manual Page 38

- Page / 56

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

TP-5700 7/9326 Section 6 Fuel Systems

1

2

3

4

TP-5700-6

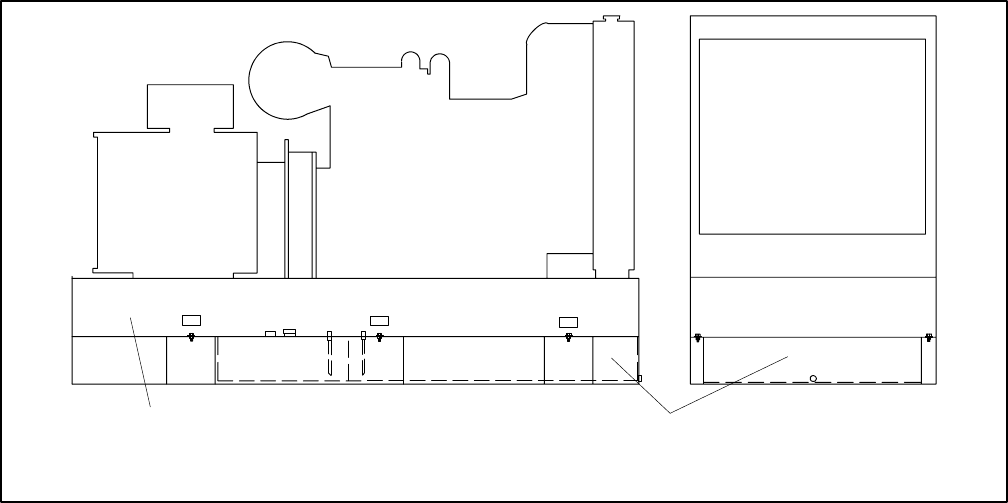

1. Generator set skid

2. Side view

3. Subbase fuel tank

4. End view

Figure 6-2 Subbase Fuel Tank

6.2 Main Fuel Tank

All main tanks should be vented so that air and other

gases can escape to the atmosphere. The vent must

prevent dust, dirt, and moisture from entering the tank.

Return lines should be spaced as far away from the

pick-up or fuel dip tube as possible. If this is not done, air

bubbles could be drawn into the fuel supply line and

cause erratic engine operation. Also, fuel returning from

the engine will be warmed from passing through the

engine. This returning fuel, if hot enough, can cause a

reduction in the power of the engine. At least 5%

capacity should be allowed in a diesel main tank for

expansion of the fuel. If the main tank is to be located

overhead, a fuel shutoff solenoid should be used to

prevent hydraulic lock or tank overflowing due to

excessive pressures c aused by static head of fuel.

Codes requiring standby power often specify minimum

on-site fuel supply. Such requirements are included in

NFPA 70, National Electrical Code; and NFPA 99,

Standard for Health Care Facilities. Diesel fuel will

deteriorate if stored for more than a year, so the tank

should not be oversized to the point that its contents

cannot be used in one year of regular exercising. If there

are no applicable code requirements, a tank sized for

eight hours operation at rated load is suggested. Refer

to the specification sheet for fuel consumption data.

Most diesel engines will operate satisfactorily on #2

domestic burner oil as furnished in most parts of the

United States. The engine can be supplied from the

same tank used for heating oil if both use the same fuel.

This is desirable both because of the cost savings and

the added advantage that fuel will be used and replaced

regularly, ensuring a fresh fuel supply for the engine.

Dual usage of the fuel can be done provided the fuel oil

meets the engine manufacturer’s minimum

requirements for such properties as wax point, pour

point, and cetane number. These factors influence cold

weather starting and power output of the

engine/generator. Where more than one engine or an

engine and another appliance(s) are fueled from the

same main tank, each engine should have its own

supply line.

6.3 Fuel Lines

Fuel lines should be constructed of Schedule 40 black

iron pipe or copper tubing. Galvanized pipe, fittings, or

tanks should never be used with diesel fuel systems.

The fuel will react chemically with the galvanized

coating, causing it to peel and clog fuel filters and

damage fuel injection components.

Fuel line sizes should be the minimum required to

deliver the volume necessary to the equipment within an

acceptable pressure drop—1 psi (0.07 kg/cm

2

). The use

of excessively large piping increases the chance that air

will be introduced into the system, and that fuel pumps

will be damaged by operating dry when priming the

system.

- 20--2800 kW 1

- Installation 1

- California Proposition 6 5 2

- Table of Contents 3

- Table of Contents, continued 4

- Accidental Starting 5

- Engine Backfire/Flash 6

- Exhaust System 6

- Fuel System 6

- Hazardous Noise 7

- Hazardous Voltage/ 7

- Electrical Shock 7

- Heavy Equipment 9

- Hot Parts 9

- Moving Parts 9

- Introduction 11

- Service Assistance 11

- Section 1 General 13

- TP-5700-1 14

- Section 2 Load and Transport 15

- 2. Lifting bars 16

- 1. Lifting fixture 16

- 2.1.1 Weather Housing 17

- 2.1.2 Sound Shield 17

- 2.1.3 Subbase Fuel Tank 17

- Section 3 Location 19

- 3.3 Mounting 20

- 3.4 Vibration Isolation 21

- Section 4 Air Requirements 23

- 4.2 Air-Cooled Generators 24

- 4.3 Forced Air 25

- 4.4 Air-Vac Cooling System 26

- 4.5 Air Vent 27

- 4.6 Liquid-Cooled Models 28

- 4.8 Remote Radiator Cooling 29

- 4.9 City Water Cooling 30

- 4.10 Cooling Tower 30

- 4.11 Block Heaters 32

- 4.12 Recommended Coolant 32

- Section 5 Exhaust System 33

- 5.1 Flexible Section 34

- 5.2 Condensation Trap 34

- 5.3 Piping 34

- 5.4 Double-Sleeve Thimbles 35

- Section 6 Fuel Systems 37

- 6.2 Main Fuel Tank 38

- 6.3 Fuel Lines 38

- 6.4 Transfer Tanks 39

- 6.5 Auxiliary Fuel Pumps 40

- 6.6 Gasoline Fuel Systems 41

- 6.7 Natural or LP Gas Fuel 42

- TP-5700-6 43

- 6.8 Flexible Connector 44

- 6.9 Gas Piping 44

- 6.10 Fuel Regulators 44

- 6.12 Vapor Withdrawal Systems 45

- 6.14 Dual Systems 45

- (Natural and LP Gas) 45

- 6.15 Natural Gas 46

- 6.16 Combination Gas-Gasoline 46

- 7.1 Batteries 47

- 7.2 Electrical Connections 48

- 7.3 Load Lead Connections 48

- 7.4 Terminal Connector Torque 49

- Remote Annunciator 50

- 14-Relay Dry Contact Box 50

- Front View Side View 50

- GENERATOR JUNCTION BOX 52

- Appendix A Abbreviations 53

- TP-5700 7/93d 56

(52 pages)

(52 pages)

Comments to this Manuals